Boxes

The DACS-GN-SE Series checkweigher is the perfect entry point for high-speed checkweighing. This model features all essential elements for a simple system that seamlessly fits your production line.

The DACS-GN-SE is available in two models depending on your factory environment, the SS model for dry environments and the WP model for wet or dusty environments.

Using patented technology, our performance-line checkweigher is engineered for weighing accuracy that meets your requirements.

The SS variant is engineered for dry environments, with a protection against ingress in accordance to industry-standard IP54 rating. It is designed for wipe-down cleaning, with aluminium conveyor beds delivering strength without providing unnecessary weight loading to the weigh cell.

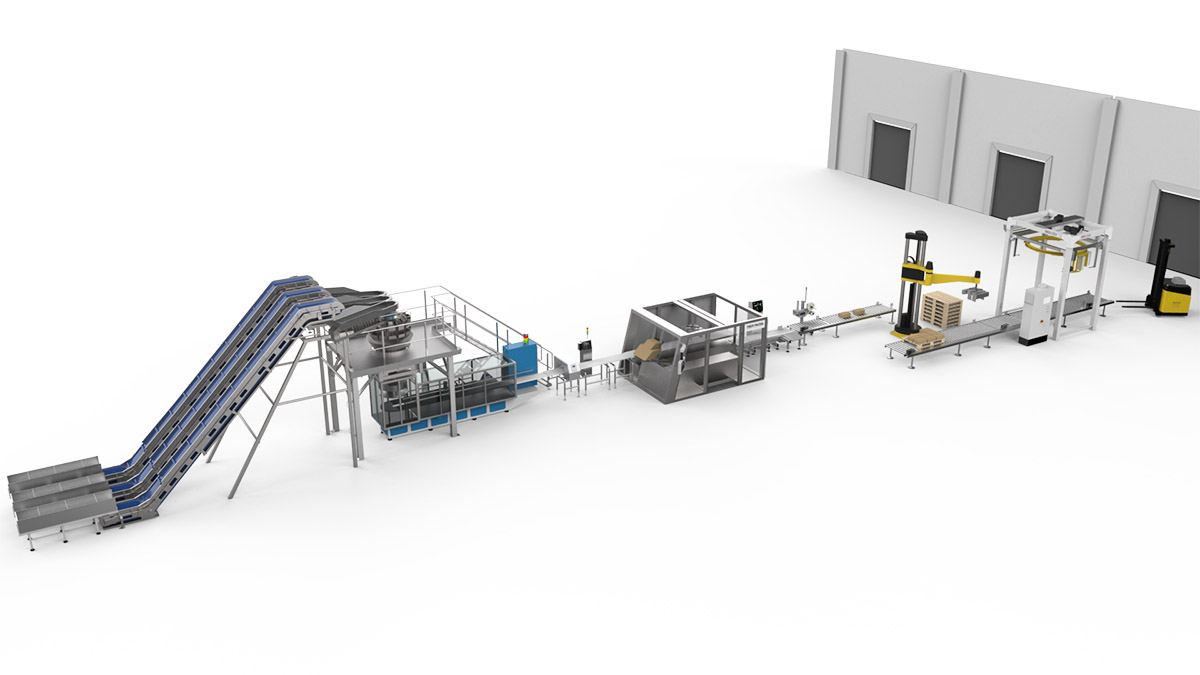

A multihead weigher or computer combination weigher (CCW) is an industrial weighing machine which delivers highly accurate, reliable and high speed weighing of food and non-food products.

Ishida has offered virtually every known CCW application solution.

The multihead weigher was invented and developed by Ishida in the 1970s. Since then Ishida has provided weighing equipment for thousands of food and non-food applications with more than 50,000 machines installed.

Machine for the packaging of products in different materials: wrap around packaging, trays, plateau packs and cardboard boxes. When used in combination with the lidding module, it can also create packages with tray and lid, both internal and external.

Either flat or standing products can be packaged depending on the configurations and arrangements. Special applications are available upon request. The machine envisages conformity checks on incoming products and outgoing packaging.Extremely compact and versatile, the WR features great multifunctionality. Large capacity, easy-to-load carton store. Highly accessible, ergonomic and user-friendly thanks to the large HMI panel.

The machine comes standard with a hot-melt package closing module, however, it can also be fit with taping module that integrates seamlessly into the machine body. The WR-S-E can be fit with automatic format change and numerous accessories to increase the degree of customization to meet your needs.

The Skilled 504 is an electro mechanical robot with articulated cinematic structure type SCARA with 4 interpolated axes, and a working area of 360°. Our first SCARA robot (Selectively Compliant Assembly Robot Arm) was launched in the market in 1996 and since then it has been installed in over 1000 plants worldwide. Thanks to its high flexibility and possibility to customize the pick-up tool for illimitated range of applications (cardboard boxes, bundles, heat-shrunk trays, bags, cans, reels, etc.), the Skilled 504 has been used to solve a wide variety of end-of-the-line product handling problems in the most diverse plant logistic situations. Its friendly and powerful programming method has been developed in Visual Basic completely by our engineers on the basis of 30 years experience in the palletizing field, in order to quickly carry out any kind of personalization at any time.

Ideal for palletising multiple lines.

- Clever design to work also in a narrow working area

- Payload 120 kg including gripper

- 4 axes

- 800 cycles/hour

The SATURN S4 wrapper has been designed to cover the markets with medium productions, up to 60 pallets / hour, being the best alternative to the arm wrapping machine.

The SATURN S4 wrappers equip the best technology available on the market, as well as the rest of our models with higher productive capacity, with electronic tension control and self-adjusting according to the load profile, which prevents film breakage or deformation of the load, ensuring maximum stability with the minimum film consumption.

Designed to handle larger products, you can now have the benefits of a high-speed checkweigher for your boxes and cartons.

The specialist Carton Line checkweigher offers impressive belt speeds and weighing accuracy as granular as 1g, to give you the quality assurance you desire.

This model is also supplied with a remote RCU tower for correct product positioning, as well as a variety of customisable features to suit your exact needs.

The PB model is engineered for dry environments with a protection against ingress in accordance to industry-standard IP30 rating.

The range of our vertical cartoning machines starts from models for carton packaging with a standard range from a minimum of mm 60 x 30 x 120H up to a maximum of mm 350 x 150 x 400H. Our machines are normally with continuous advancing, continue and alternate or only alternate and allow a high flexibility to be adapted to different customers’ needs.

Minimum production can be from just a few cartons per minute for some models, to reaching a maximum production of 320 cartons per minute for the fastest models.

Skilled LGV (Laser Guided Vehicle) is an automatic fork lift truck which, together with our palletizing systems, allows complete “end of line” automation. This results is cost savings and significant improvements in production management.