Slide Gates & Diverter Valves

Ideal for handling dry bulk material in gravity flow, dilute phase or dense phase pneumatic conveying applications. Vortex slide gates and diverters are designed and engineered with two main principals in mind: 1. extend the service life of the valve and 2. perform maintenance without taking the valve out of line. Vortex valves serve many industries including chemical, cement, coal, food, frac sand, grain, minerals, petrochemical, pharmaceutical, plastics, polymer, rubber and mining.

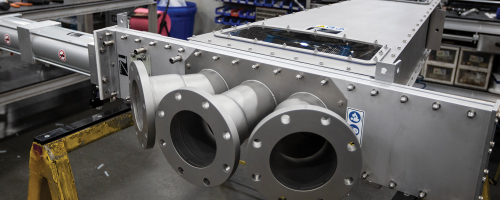

Vortex Quantum Series slide gates and diverters are the valves our customers have been using for decades to shut off, meter, and divert their dry bulk material. It’s our traditional line of valves for dry bulk processing and conveying through gravity flow or pneumatic (pressure or vacuum) conveying.

Some of the industries that use Quantum valves include but not limited to: agriculture, chemical, coffee, dairy, foods, milling, pet food, petrochemical, pharmaceutical, plastics, rubber, textiles, tobacco, and wood – to name a few.

Vortex Titan Series slide gates and diverters are engineered for HEAVY-DUTY material handling applications. These applications include materials that pose excessive abrasion or wear issues, situations that call for extremely large-sized valves and diverters, and conditions that warrant additional considerations that will allow these valves to be as successful as possible in extremely harsh environments.

Some of the materials handled with Vortex Titan valves include but not limited to: alumina, bauxite, cement, clinker, coal, fly ash, frac sand, gravel, glass cullet, lime/limestone, metal powders, potash, rock and sand – to name a few.

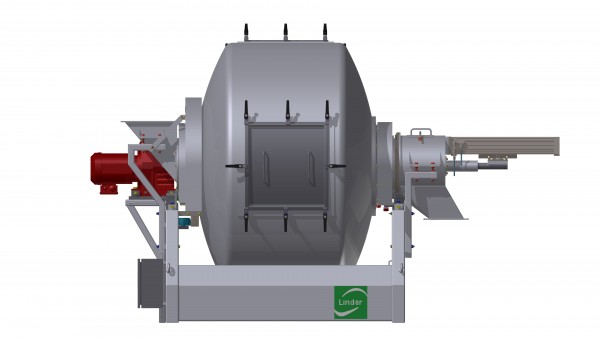

Loading Solutions offer a complete line of telescopic loading chute systems for the loading process. We also custom engineer any loading spout system to meet the most demanding loadout application requirements, including corrosive or hazardous materials, long distances, low and high temperatures, etc. Vortex fully assembles, factory tests and packages every loading spout system before shipping it to the facility to provide ease of installation and to ensure optimal performance once in use.

Some of the materials handled with Vortex Loading Solutions include but not limited to: petrochemical powders, plastic granules, wood pellets, cement, grains, sand, gravel, or coal. – to name a few. And can be used in open, semi-enclosed and closed vessels: trucks, railroad cars, tankers, ships, barges, and open-stockpiling.